Futureproofing Your Supply Chain with Best Cable Electric Wire Trends for 2025

As we approach 2025, the landscape of the Cable Electric Wire industry is poised for significant transformation driven by technological advancements and shifting market demands. According to a recent market report by Research and Markets, the global cable wire market is expected to grow at a CAGR of 4.7% from 2020 to 2025, reaching a valuation of $197 billion by the end of this period. This growth is largely attributed to the increasing adoption of renewable energy sources and the ongoing expansion of smart grid technologies, which require more sophisticated Cable Electric Wire solutions. As businesses strive to futureproof their supply chains amid evolving regulations and sustainability targets, understanding these trends will be crucial.

In this blog, we will explore the emerging best practices and innovative solutions that are shaping the cable electric wire sector, helping industry players stay ahead in a rapidly changing environment.

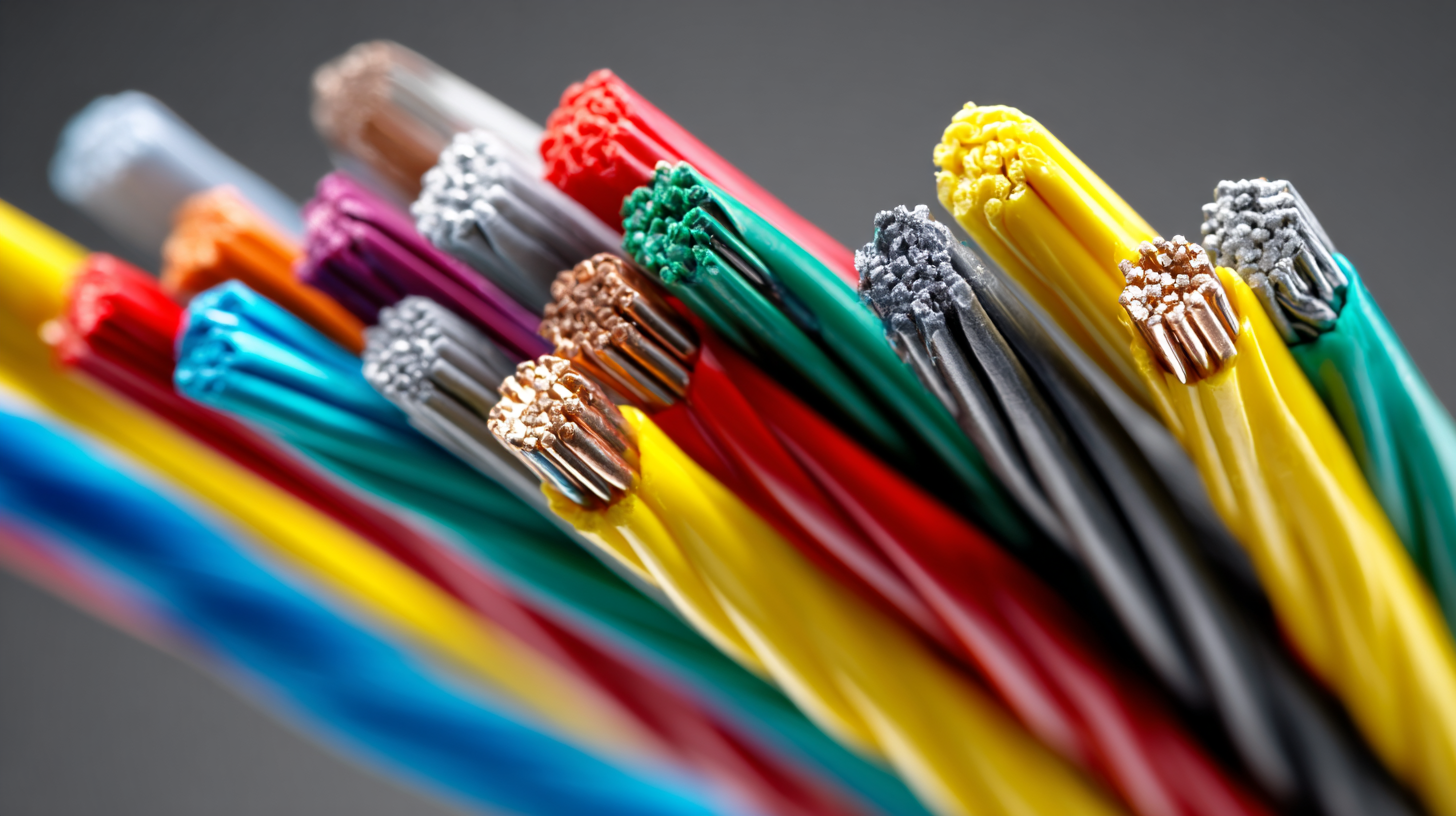

Exploring Key Innovations in Cable Electric Wire Technologies for 2025

As we look toward 2025, the cable electric wire industry is poised for significant transformation driven by key innovations that promise to enhance efficiency and sustainability. According to a recent report from MarketsandMarkets, the global electric wire and cable market is projected to reach $211.08 billion by 2025, growing at a CAGR of 6.9%. This growth is largely attributed to the rising demand for renewable energy and the expansion of smart grid technologies, which rely heavily on advanced conductor materials and insulation techniques.

One notable trend is the increasing adoption of high-performance cables designed for extreme environments. These cables are engineered using advanced polymer materials that offer outstanding thermal resistance and mechanical strength. The International Electrotechnical Commission (IEC) has recognized these innovations in their standards, underscoring their importance in the evolving electrical landscape.

Additionally, the integration of Internet of Things (IoT) technology into cable monitoring systems is revolutionizing maintenance practices, allowing for predictive analytics that can reduce downtime and enhance safety. This intersection of technology and materials science is not only futureproofing supply chains but is also essential for meeting the energy demands of the future.

Integrating Sustainable Practices into Your Supply Chain Management

As the global focus on sustainability intensifies, many industries are reevaluating their practices to align with eco-friendly standards. In the cable electric wire sector, integrating sustainable practices into supply chain management is becoming increasingly essential. According to a report by Allied Market Research, the global green cable market is expected to reach $4.57 billion by 2025, highlighting a robust shift towards environmentally responsible materials and practices. This shift not only addresses regulatory pressures but also caters to the growing consumer demand for sustainable options.

Embracing sustainable supply chain practices means prioritizing materials that minimize environmental impact. By sourcing eco-friendly raw materials and optimizing production processes, companies can reduce their carbon footprint significantly. The adoption of circular economy principles, such as recycling and reusing components, is also gaining traction. For instance, the International Cablemakers Federation reported that 70% of their member companies are now committed to reducing waste through comprehensive recycling programs. By integrating these sustainable practices, organizations not only futureproof their supply chain for 2025 but also contribute positively to the environment, creating a competitive edge in the market.

Adapting to Regulatory Changes Impacting Cable Electric Wire Industry

As the cable electric wire industry faces evolving regulatory changes, it is crucial for businesses to adapt swiftly and strategically. These regulations often aim to enhance safety, foster sustainability, and promote energy efficiency, shaping how products are designed, manufactured, and marketed. For industry players, staying informed about compliance requirements at both local and global levels is essential. By investing in knowledge and tools to meet new standards, companies can not only avoid penalties but also enhance their market position.

Moreover, embracing innovative practices in response to regulatory shifts can lead to the development of cutting-edge products that align with consumer demand for sustainability. For instance, utilizing recyclable materials and improving energy efficiency in wire production can not only comply with regulations but also attract environmentally-conscious customers. This proactive approach not only mitigates risks but can also serve as a competitive advantage in a rapidly changing marketplace. By anticipating these changes and integrating them into their business strategies, companies can future-proof their supply chains and thrive in the coming years.

Leveraging Data Analytics for Supply Chain Optimization in Wiring Solutions

In the ever-evolving landscape of supply chains, leveraging data analytics is paramount for optimizing wiring solutions. As we approach 2025, the usage of precise data insights allows businesses to identify trends, predict demand fluctuations, and enhance operational efficiency. By harnessing advanced analytics, companies can navigate complexities, enabling timely decision-making that bolsters their supply chain resilience.

To maximize the benefits of data analytics, companies should adopt a few key strategies. First, invest in integrated software that consolidates data from various sources, providing a comprehensive view of supply chain dynamics. Second, prioritize training programs for staff, ensuring they are equipped to interpret data insights effectively. Third, establish a culture of continuous improvement, using analytics to iterate on processes and adapt to new market conditions.

As the electric wire industry grows, it’s essential to remain ahead of the curve. Utilizing predictive analytics can help forecast future wire trends, allowing companies to allocate resources efficiently and respond swiftly to market changes. Embracing these analytical tools not only enhances performance but also paves the way for long-term sustainability and competitiveness in the supply chain.

Futureproofing Your Supply Chain with Best Cable Electric Wire Trends for 2025

| Trend | Impact on Supply Chain | Data Analytics Application | Projected Outcomes (2025) |

|---|---|---|---|

| Sustainable Materials | Reduced environmental impact, enhanced brand image | Predicting material trends and sourcing options | 30% reduction in carbon footprint |

| Smart Manufacturing | Increased efficiency and reduced costs | Real-time monitoring and predictive maintenance | 20% decrease in operational downtime |

| Supply Chain Transparency | Enhanced trust and accountability | Blockchain for secure, transparent tracking | 40% improvement in traceability |

| Data-Driven Decision Making | Improved forecasting and inventory management | Advanced analytics and AI modeling | 15% increase in customer satisfaction |

| Automation and Robotics | Reduced labor costs and increased precision | Data analysis for workflow optimization | 25% increase in production capacity |

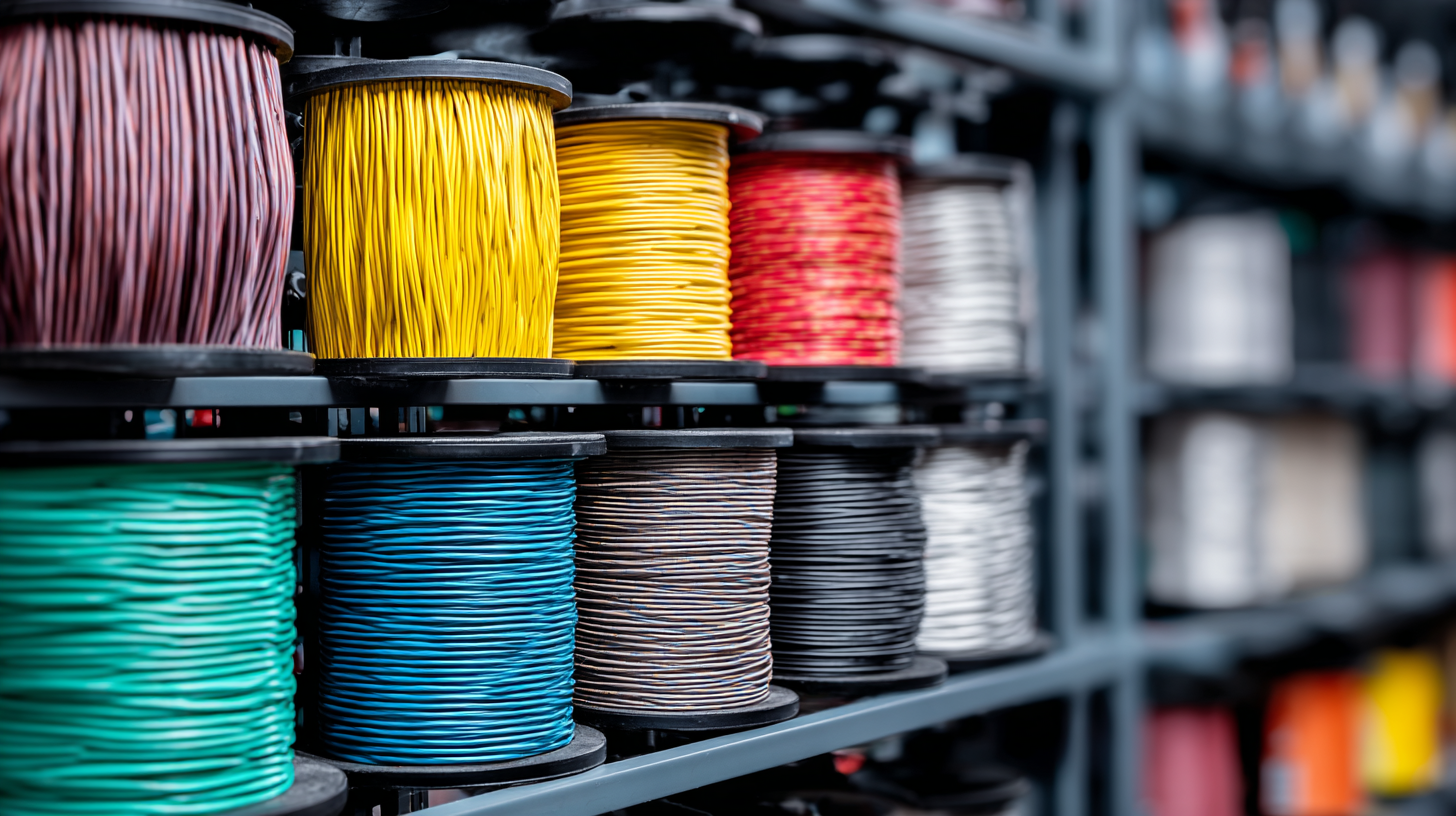

Building Resilience Against Supply Chain Disruptions Through Strategic Sourcing

In the evolving landscape of global business, supply chain resilience has emerged as a critical focus for companies aiming to navigate disruptions effectively. As we look towards 2025, one of the key strategies in building this resilience is strategic sourcing, particularly in relation to innovative materials like environmentally friendly silicon dioxide. The demand for such materials is rising across sectors, including automotive and personal care, indicating a shift towards sustainable procurement practices.

Tips for enhancing supply chain resilience include establishing strong partnerships with suppliers to ensure a reliable resource flow and adopting diversified sourcing strategies to mitigate risks associated with over-reliance on a single region, such as China. As multinational companies reassess their supply chains, leveraging advanced technologies to create cognitive supply chains can facilitate better decision-making and responsiveness to market fluctuations.

To remain competitive, businesses should also invest in understanding market trends and consumer demands, which will play a pivotal role in shaping procurement strategies. By prioritizing strategic initiatives today, companies can futureproof their supply chains against uncertainties in the years to come.

Futureproofing Your Supply Chain: Cable Electric Wire Trends for 2025

This chart presents the projected growth trends of different types of cable electric wire used in supply chains, focusing on resilience against disruptions. The data covers the years 2023 to 2025.